Tus neeg

Yog li cas cov chiller siv hauv tsoom fab ua ua “tus poj ntxoog tsis hais lus” nyob hauv kev tsim kho lub pob ntawm carbon crystal thiab lub thawv hlau hlau

Qhia tshwm sim: thaum kub txib tshaj tshuaj sov

Txhua hnub nyob hauv peb lub tsev haujlwm nyob Su Zhou, ob hli ntawm dej ntaub yaj raug kub txib mus rau qhov chaw tso tawm los ntawm kev siv dej ntaub. Yog tsis muaj qhov chaw sov tshaj tshuaj ntxiv, cov khoom tshuaj tshaj no yuav tshav tawm rau thaum kawg—rau tib yam li cua sov tawm ntawm nws lub tshuab tshaj. Qhov no yog qhov tseem ceeb tshaj plaws rau “ob yeeb kwm” ntawm kub tshaj tshuaj—lub chiller tshaj tshuaj thiab lub tshuab tshaj kub tshaj tshuaj. Txawm tias peb yog tus neeg tsim khoom nyob Su Zhou thiab tseem ceeb rau kev tshawb fawb hauv chaw tshaj kub tshaj tshuaj, peb xav mus saib ntau yam kev siv tshuaj tshaj tshuaj hauv ob qhov chaw tshaj tshuaj tseem ceeb: carbon crystal panel thiab plastic pipe production lines.

Ntu 1: Ib qhov kev tshwm sim phem uas tseem ceeb

Kev tsim tshuab roj tog hlwb yog tib yam li kev laj thaum sijhawm. Tus tshuab kuaj xyuas dej tso cua sov rau roj tog hlwb mus rau qhov tshwv yeej txaus siab, thiab thaum pib tsim tshuab, nws yuav tsum tau raug sov kom ncaws mus rau hauv qab kom "tho" lub tsheb thiab qhov nyiaj. Dej, vim nws muaj zis tshuaj sov siab, nqi tsawg, thiab yooj yim los tso tawm, yog tus kheej tseem ceeb tshaj plaws los sov nruj. Thiab qhov cheeb tsam ntawm chiller yog txhawb kom dej no tso tawm tas li, zoo ib yam, thiab ruaj khov nyob rau hauv qhov cua sov koom tes.

Xaiv tias muaj ib qhov roj tog hlwb tshiab tshuab tshuab. Yog tias nws tsuas yog raug sov nrog dej tsha, lossis los ntawm kev sov tsha, nws yuav tsum meem tawb, rov tav, lossis muaj kab nrog rau saum npoo nws vim kev sov tsis zoo ib yam. Nyob rau hauv qhov chaw ua haujlwm uas muaj kev tswang siab, cov khoom no tsis tuaj yeem.

Ntu 2: Kev pom zoo nyob ze – Chillers nyob rau hauv kev tsim kho tshuab carbon crystal panel

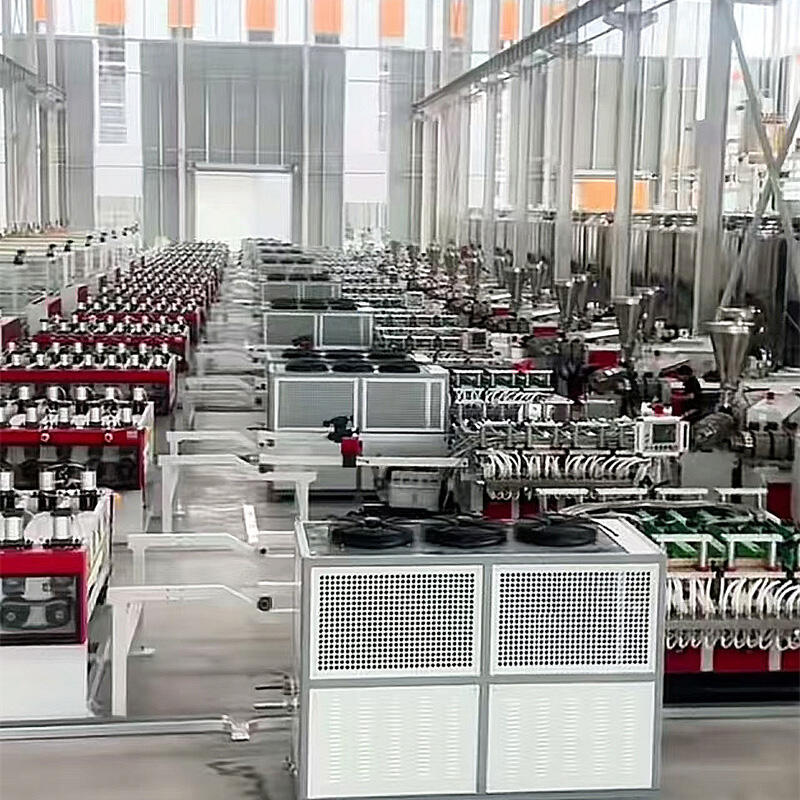

(ob ob zaug no yog tshooj hluas nyob ze kawg ntawm qhov chaw tsim khoom ntawm cov carbon crystal panels, nyob saum npoo ntawm carbon crystal plate extrusion mold, ib daim ntawv hlub muaj zog tuaj yeem pom tias nws tseem ceeb ntau hauv qhov rooj tshuab tso dej, thaum kawg ntawm sab nraud ntawm qhov rooj tshuab tso dej, ib qhov chiller muaj li 20hp muaj siv rau kawm ntau tseem ceeb ntau, tso kawm ntau rau nws tas li.)

Carbon crystal plates, ib qho khoom siv ntau rau kev sib cuag zoo thiab kev siv khoom zoo, muaj qhov kev cai nyuaj rau kev tso tawm, kev sib xws thiab kev sib cuag zoo. Qhov kev tsim khoom no yog ib qho kev sim tshaj plaws rau kev tso tawm kawm ntau.

Yog li cas chiller no yuav tshaj tawm?

1. Kawm ntau tshaj: Cov carbon crystal plates, muaj kawm ntau txog 150℃, tuaj yeem tshaj tawm hauv qhov rooj tshuab tso dej tom qab tshaj tawm hauv qhov rooj tshuab tso tawv ntau.

2. Kawm Txoj Cai Ua Ntuj Ci: Lub chiller 20hp tiv thaiv hluv uas peb muab kho tau yuav kawm ceev qhov txoj cai ntawm lub thawv dej hauv qhov tsim nyob rau hauv qhov cai 5℃ - 15℃ (yuav raug hloov tam sim nkaus rau hauv khoom siv thiab kev ntev). Qhov kawm hluv no yuav tiv thaiv kev nqus thiab kev ua kom raj nqaij nqus los ntawm kev tsis zoo ntawm kev nqus hauv plhaub.

3. Saib xyuas Phaub: Qhov kawm hluv pab tshwm sim ib qhov surface smooth thiab zoo li mirror, uas yog qhov tseem ceeb rau kev tshwm sim siab sib piv thiab qhov kev xwm yeem ntawm phab ntsa carbon crystal.

4. Ke Vam Thiab Tswj Fwm: Lub tshuab kawm qhov temperature ntawm qhov dav hlau ntawm qhov chaw tsim khoom yuav pab kom khoom siv raug thawj tag nrho thiab muaj kev sib luag zoo; lub chiller nyob qhov dav hlau ntawm qhov chaw tsim khoom yuav "tsim" lawm tam sim. Qhov sib txuas zoo no ntawm kev kawm thiab kev kawm hluv yog qhov tseem ceeb tshaj plaws rau kev tsim khoom phab ntsa carbon crystal muaj qhov zoo thiab ntau.

Zog nqi: Qhov kev kho tom qab siv tshuab rau cov plhaws tau hloov me me, uas tsawg kawg rau qhov tsis txaus, thiab tseem pib txuas ntxig ntau dua li 15-20%.

Ntu 3: Sau ntawv nyob ze qhov chaw – Chillers nyob rau hauv kev tsim kho tshuab tsim khib nyiab

(Peb tus neeg sau ntawv tau ua rau qhov chaw tsim kho khib nyiab: Lub ntsiab lus tseem ceeb ntawm lub thawv ntim dej tso tshuaj tso tshuaj tso tshuaj, uas muaj ntau khib nyiab sib txawv ntim hauv. Nyob sab nraud, lub chiller siv zog ntau sib ntxig rau lub thawv los ntawm khib nyiab, tsim ib qhov kev sib ntxig kawg.)

Cov khib nyiab PVC/PPR rau kev tso dej tso dej thiab tso dej tso dej peb pom tag nrho nyob hauv kev nyob tag nrho kuj tseem tshwm sim los ntawm qhov “quenching” ntawm dej tso tshuaj. Kev sib tso tshuaj tom qab khiav tsis yog ib qhov kev txo su temperatures; nws yog ib qhov kev “calibration”.

Yog li cas lub chiller no pab kho dab tsi?

1. Tsis txhob rov qab rau kev tsis muaj zog: Lub tub lag luam plastic npuas siab yog qhov nyuaj rau tshuab ntau. Lub dej noo uas muab los los ntawm lub chiller tuaj yeem ua kom lub tub lag luam plastic npuas siab hlo sib tshooj rau hauv lub vacuum calibration tank, kom zoo siab tias nws tuaj yeem tso caij nrog lub tog raj kheej thiab lub dav hlau tswv yim. Xa mus li, kev siv ib lub chiller tshiab rau txhua lub tshuab extrusion tub lag luam npuas siab tau dhau los ua kev nyiaj cuab nyob hauv cheeb tsam.

2. Sauv kev hloov pauv: Plastic yuav hloov pauv thaum nws ncav. Tus nqi temperature ntawm lub dej yuav tsum muaj kev tshwm sim sib xws. Peb lub chiller siv qhov kev coj ntawm PID kom sauv kev hloov pauv hauv ±1°C, kom txoj kab npuas siab zoo ib yam thiab tso caij tsis muaj qhov chaw nyuaj.

3. Kev tshawb pom kev tsim kho tshuab ntau: Kev tsim kho tub lag luam plastic feem ntau tuaj yeem tshuab ntau 24/7. Qhov nyuaj thiab kev tseem ceeb ntawm lub chiller yuav tsum raug kos. Peb siv lub compressor meej, evaporators tsi mob, thiab plate heat exchangers kom sauv kev tso dej noo tsis hloov thaum siv ntev thiab ntau.

4. Siv Ntau Qhov Ruaj Khov: Cov chiller tshiab, xws li peb cov chiller kis rau av uas peb xav kom tau siv cov hluv tshaj tshuab thiab cov ceev tshaj tshuab uas muaj zog siab los rhuaj rhib kho qhov zog txiav txim siab ntawm qhov load nyob ze, txav rau neeg siv ntau txhua xyoo ntau li 30% dua li cov cuar tshiab.

Ntu 4: Vim Li Cas Yeej Xaiv Ib Lub Chiller Kawm Txoj Hauj Lwm?

Txhawm rau ib lub chaw tsim khoom, peb paub tias ib lub chiller zoo yuav tsum ua ntau dua li just “kis.” Nws yuav tsum muaj:

- Sau Los Rau: Sib phim rau hauv koj lub tshuab tsim khoom, kev siv khoom, thiab daim duab khoom (xws li 20HP, 30HP, 50HP) kom tso tseg kev tsis tu ncua lossis kev puv zog.

- Muaj Siab Thiab Ruaj Khov: Tshuab tswj kom plob, tshuaj txaus siab, tiv thaiv kom tsis kis, thiab ntau ntxiv, rau kev siv sai thiab nyob siab dua.

- Tsom Los Rau Daim Siab: Cov khoom siv tseemceeb muaj kev tsim kho kom tiv thaiv roj tsha, kom tiv thaiv roj khaum huv uas siv nyob rau hauv kev tsim khoom hlau, kom ntau dua.

- Txhawj Xyuas Tshaj Plaub: Peb muab kev pab ntau txog txhua yam—ntawm kev saib xyuas chaw, tsim kho kev daws teeb meem, pab tshiab kev xaiv thiab kev saib xyuas tom qab siv khoom.

Sau ntawv: Nhi txhiab—Qhov Siab Tshaj Hlub Ua Haujlwm

Nyob rau hauv qhov chaw tsim kho cov ntoo thiab cov kab ntsug rau carbon crystal, tus tso ntoo hla yog "dab neej tso tseg," thiab tus kho ntoo yog "yeeb kwm." Tab sis, tus chiller tsis tu ncua yog "Dab Neeg Tsaug" nyob sab nraud. Nrog rau nws qhov tseem ceeb hauv kev saib xyuas nhi txhiab, nws pab tseg kom txhua lub ntoo zoo ib yam thiab txhua lub kab ntsug muaj qhov loj me zoo, thiaj li pab rau peb cov neeg siv khoom tau txais kev sib tw zoo tagnrho hauv tshwj xeeb thiab hauv kev lag luam.

Yog tias koj tab tom xav nrhiav lossis hloov kho koj lub tso ntoo hla rau plastic, ces yog qhov yooj yim los nyem ntau dua ob tshuab hauv kev paub txog "Dab Neeg Tsaug" no. Kev xaiv ib tug neeg thwjpab yuav pab koj muaj kev pab hauv kev tsim khoom zoo dua thiab khoom zoo dua.